thickness of glue layer test|testing for adhesive strength pdf : trading Introduction. Adhesive bonds are frequently used in numerous industrial sectors [,]. Adhesive bonding is a particularly attractive assembly technique for application in which .

WEBAUD-20231110-WA0035 AUD-20231110-WA0035 Clonación terapéutica. Clonación terapéutica. 00:00. 02:34. Share Like Liked Download Like Liked .

{plog:ftitle_list}

WEBSuspensão tipo multibraço e traseira com barra estabilizadora, roda tipo independente e molas a ar. BMW X6 4.4 M 2024: Ficha técnica completa. Motor, performance, dimensões, consumo, mecânica .

This review discusses potential measurement methods for characterising and quantifying the interfacial adhesion strength properties that are key to the strength of bonded systems. Some. The mechanical properties of the structural adhesive were investigated under room temperature dry state (RTD) and elevated temperature wet state (ETW, 71 ℃/85% RH), and .

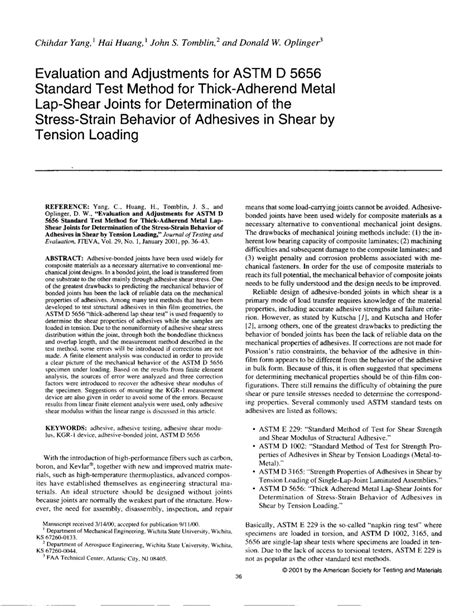

testo 320 basic flue gas analyzer

Typically, the shear properties are measured using the thick lap shear test, because this is the typical loading mode of structural adhesive bonds. The hardening rule defines how the yield . Understanding the relative merits and limitations of these tests, and meaningful ways to analyze the results, is essential for current and emerging applications – from tough, .This guide is an educational tool designed to aid adhesive users in gaining a more thorough understanding of adhesive properties and testing methods. It was compiled through the .

Introduction. Adhesive bonds are frequently used in numerous industrial sectors [,]. Adhesive bonding is a particularly attractive assembly technique for application in which .

what is flue gas analyzer

The adhesion strength of thin films is critical to the durability of micro and nanofabricated devices. However, current testing methods are imprecise and do not produce quantitative results. The test results show that the thickness of the bond layer did affect shear strength development in the epoxy adhesives examined. Keywords: epoxy adhesive, adhesive layer .Results from thick adhesive joints (notched lap shear joints, shown in [Citation 322]) reveal a significant effect of the overlap length, adhesive thickness and applied load direction (tension .The research devoted to the adhesive layer thickness and its effects is considerable [Citation 220–227] as few examples. Various, contradicting results are obtained. . usually made by thick adherends and thick paste adhesive bondlines. Each test can provide important data for thick paste adhesive joints under a full range of loading .

how to flue gas analysis

The important difference between the two test set-ups, using plastically deforming adherends, is the different thicknesses of the adhesive layer. With a 1 mm thick layer, the adhesive is considerably softer; the compliance scales

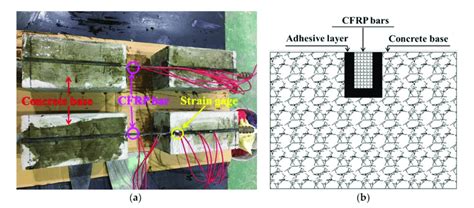

Essentially, as the thickness of the adhesive layer is increased in the peel test specimen, a larger volume of adhesive is subjected to deformation per unit area of detachment so that the energy expended increases. However, at large thicknesses the energy dissipated in the zone at the crack tip then becomes independent of the overall thickness . Furthermore, the FPZ for the adhesive layer thickness of 5 mm was the longest; it was approximately 18.7 % longer than that for the test specimen with an adhesive layer thickness of 2 mm. In terms of structural load-bearing capacity and fracture toughness, the concrete-epoxy resin interface exhibited the best working performance when the . The thickness of the adhesive layer had a significant effect for a semi-rigid acrylate adhesive, where the joint achieved higher strength values with less thickness of the glue. . We have also studied the influence of the thickness of the adhesive layer, to test the premiss that greater thickness of the adhesive layer leads to greater . Good agreement between the test results is achieved for thin layers in both fracture modes. For thicker layers the variation is larger. . Remarkably, when the adhesive layer thickness is on the .

The effect of the adhesive thickness on the bond strength of single-lap adhesive joints is still not perfectly understood. The classical elastic analyses predict that the strength increases with .

The intermediate layer is applied by spin-on, spray-on, screen-printing, embossing, dispensing or block printing on one or two substrate surfaces. The adhesive layer thickness depends on the viscosity, rotational speed and the applied tool pressure. The procedural steps of adhesive bonding are divided into the following: [1]

(a,b) The intra-test CV trends changed to a decreasing trend after peel rate of 0.707 mm/sec for both PTFE and PEEK demonstrating that the asynchronous failures of filaments of adhesive layer is . The shear strength of an acrylate adhesive layer 2 mm in thickness is approximately 30% lower than the shear strength of a layer 1 mm in thickness, and a joint with an acrylate adhesive layer 3 mm in thickness is approximately 55% weaker than the shear strength of a layer 1 mm in thickness.

thickness of adhesive layer

thick adhesive shear test pdf

The test results show that the thickness of the bond layer did affect shear strength development in the epoxy adhesives examined. Keywords: adhesive layer thickness; brittle fracture; epoxy adhesive; slant-shear test. The adhesive resin layer thickness can affect the bonding performance of two-step UAs in high C-factor cavities. . Half of the μ-specimens per experimental group (n = 10) were immediately subjected to the μTBS test to determine the “immediate” μTBS, while the other half were first exposed to 100,000 (100 k) 5/55 °C thermocycles (TC .

In a bond joint, it is very important to have a uniform bond line thickness for optimal adhesive performance. Shim spacers can be used for keeping the bond line thickness uniform. In many cases, solid glass microspheres of different sizes (~0.001 to 0.007 inches) can be added to the adhesive to create a uniform bond line thickness.

thick adherend shear test

The separation behavior of the 1 μm thick adhesive layer at a separation speed of 0.05 mm/s is expected to be ductile, because this behavior is apparent in a 15 μm thick adhesive layer at a separation speed of 1 mm/s, considering the layer thickness and strain rate [15], [16]. The range of the recommended thickness of the adhesively bonded joint is defined in the literature as from 0.1 mm up to 4 mm depending on the type of adhesive used and the operating loads, which is compared in Davies et al. [2].Gleich et al. [10] indicates that the most optimal ratio of strength to thickness of the adhesive layer is in the range of 0.1–0.5 mm, and . The thick adherend shear test [33-37] is preferred for determining design parameters as the . thick, . Often fracture in peel tests occurs in the adhesive layer rather than .

The number of works discussing the effects of adhesive layer thickness on the strength and toughness of the joint is considerable [[3], [4] . Fig. 18.1 A–C shows three typical test specimens often used to investigate strength and fracture in adhesive joints. Download: .

The test indicated that the maximum shear stress developed when the thickness of the adhesive layer was 4 mm. The shear stress began to decline when the thickness reached 6 mm, and reached its minimum at 7 mm (see Figure 7 ). The CFD predictions of the adhesive layer thickness showed good agreement with the experimental data, with the relative differences between the average experimental and numerical thickness values ranging from 4.07% to 27.1%. . Sakoda, H.; Higatani, A.; Tabata, A. (Eds.) Slippage Test of Frictional High Strength Bolted Joints with Adhesives .

By increasing the adhesive bond line thickness up to 1.1 mm, the crack kept propagating inside the adhesive layer, however in a plane more remote from the mid-bond line thickness plane. Although the crack path approached regions really close to the epoxy-steel interface, it should be noticed that interfacial failure did not take place (a thin . Here we study how strength and toughness are affected by adhesive thickness. We sandwich gelatin adhesives of various thicknesses between glass substrates. . For each adhesive thickness, five samples are tested. Tissue adhesives can be assessed by lap shear test (ASTM F2255–05), tension test (ASTM F2256 . the layer of adhesive does not . The test indicated that the maximum shear stress developed when the thickness of the adhesive layer was 4 mm. The shear stress began to decline when the thickness reached 6 mm, and reached its minimum at 7 mm (see Figure 7 ).

One of the most relevant geometrical factors defining an adhesive joint is the thickness of the adhesive layer. The influence of the adhesive layer thickness on the joint strength has not been precisely understood so far. This article presents simplified analytical formulas for adhesive joint strength and adhesive joint coefficient for different joint loading, .

This allows the coating to perform well. The primary methods used to test paint adhesion are explained below. 1. Cross-cut test by tape test method ASTM D3359 — Standard test methods for rating adhesion by tape test This test method covers procedures to assess the adhesion of coating films to metallic substrates. This is done by applying and .Super glue (cyanoacrylate adhesives) requires very thin bond line and their final strength weakness as the bond line thickness increases. 2K Adhesive is quite the opposite as they are a gap filling material and if the bond line is smaller than a certain value (depending on the one you use) the final strength decreases and off-course it has a . The number of works discussing the effects of adhesive layer thickness on the strength and . The tensile pull-off test utilizes a polymeric glue to attach an actuator to the surface of a coating .

To prepare the single-lap adhesive joints (SLJs) with different micron thicknesses of bondline, a special tooling was designed, as shown in Fig. 1.The basic principle and the geometrical parameters of the tooling and the specimen were described in detail in our previous work [32].The thickness of the Al substrate is 5 mm, the overlap width is 25 mm, and the .

types of flue gas

fluke flue gas analyser

Esta pequena ilha em 3 dimensões é toda sua para explorar .

thickness of glue layer test|testing for adhesive strength pdf